Use this manual if your electric winch has a gray cover, it operates on a 12 volt battery, it has a strap, and it has a handheld remote switch.

Find in the list below the problem you are experiencing with your winch, then click the “+” sign near a “Possible Cause” for an explanation of how to fix it.

Symptoms & Solutions

Motor will not run

Corrective Action:

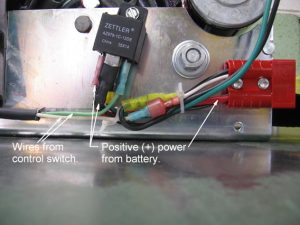

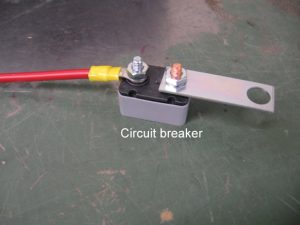

Make certain that 12 volt power is getting to the winch. If you can hear the relay make a click noise when you push the RUN switch, then power is present and you can proceed to the next trouble shooting step. If not, check the battery and the connection of the wiring harness to the battery. The most common problem is an insufficient ground connection on the negative wiring harness wire. It is possible to measure 12 volts at the winch with a meter, but have a ground connection that will not allow sufficient current to run the motor. Disconnect and clean the ground connection and reassemble. Check to be sure that the red connector on the end of the wiring harness is securely snapped into the mating connector on the winch and that all four wires going to this connection are secure. If these steps do not solve the problem, check for a faulty circuit breaker by temporily removing it from the system. Also check the entire length of the wiring harness for a broken wire. Once you confirm that 12 volt power is getting to the relay inside the winch, then proceed to the next trouble shooting steps.

Corrective Action:

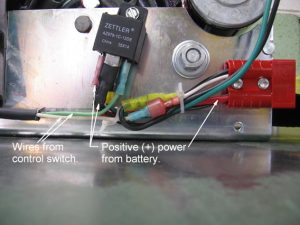

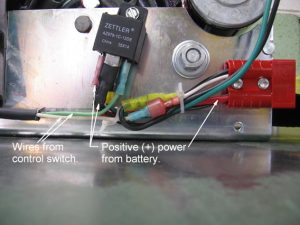

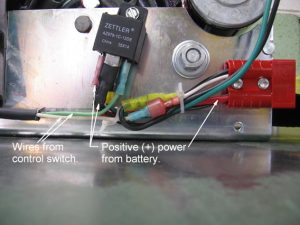

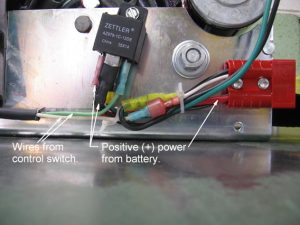

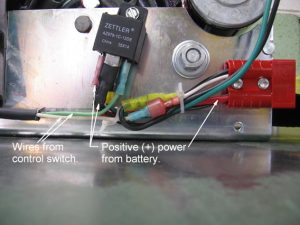

Because this winch only runs in one direction, reversing the battery wires will cause the motor to immediately stall when the switch is activated. If when the switch is activated, the motor attempts to run and immediately stalls, check to be sure the positive harness wire is connected to the positive (+) battery terminal and that the rest of the wiring is exactly as shown in the diagram.

Corrective Action:

If the relay makes a click noise when the switch is pressed, but the motor does not run, remove the green motor wire from the relay. Then using jumper wires, touch the green motor wire directly to the positive (+) terminal of a 12 volt battery and the black wire to the negative (-) terminal. If the motor fails to run, or runs erratically, it needs to be replaced. Order number 306235. If the relay does not click when the switch is pressed, proceed to the next trouble shooting step, but you may need to come back and test the motor later.

Corrective Action:

Check for loose or broken wires at the plug where the remote switch connects to the winch. Slide back the rubber boots on both halves of the plug and make sure all wires are securely connected. Also confirm that this plug connects white to white and green to green. Note that there may be color markings on the plug. These are incorrect and should be ignored.

Corrective Action:

You should be able to hear a click noise when the relay is activated by the switch. If you can hear the relay clicking, then you can rule out the switch and switch wiring as sources of the problem. If the relay does not click as described above, unplug the control cord from the winch and use a continuity meter to test the switch. Pull the rubber boot on the plug back so you can see the wires. With the switch in the OFF position there should not be continuity between any of the prongs on the plug. With the switch pushed in the RUN direction, there should be continuity between the prongs with the white and green wires. If the switch does not operate as described, replace the switch assembly number 306237. If you are certain the switch cord is not damaged and you want just the switch, you can order switch number 204490. If the switch did operate correctly, then test to be sure the switch signal is getting to the relay. Plug the switch back onto the winch and then disconnect the white and green switch wires from their connections. Be sure to make note of where the wires belong. Check continuity between the two wires. With the switch in the OFF position there should be no continuity between the wires and with the switch pushed in the RUN direction, there should be continuity. If everything does not work as described, then go back to Step 3 (Motor failure) and double check the wiring at the plug and check for any damaged or broken wires between the plug and the relay.

Corrective Action:

Examine all of the wiring inside the winch cover for broken wires or loose connections.

Corrective Action:

After confirming that there is power to the winch (Step 1), that the switch is working properly (Step 5), that the motor is not burned out (go back and test it as described in Step 3), and that the wiring is O.K. (Step 6), then the only possibility left is the relay. Order and install a new relay number 206439.

Winch motor continues to run when switch is released

Corrective Action:

First, unplug the switch cord from the winch. If this causes the winch to stop, then the switch is faulty and needs to be replaced. Order switch number 306237. If this did not stop the winch, then replace the relay 204639.

Winch runs immediately when power cord is attached

Corrective Action:

First, unplug the switch cord from the winch. If this causes the winch to stop, then the switch is faulty and needs to be replaced. Order switch number 306237. If this did not stop the winch, then replace the relay 206439.

Motor runs hot

Corrective Action:

Limit motor run time to a maximum of three minutes followed by at least 20 to 30 minutes of cooling. Motor run time is critical even when winch is not pulling its full capacity.

Motor has difficulty pulling load

Corrective Action:

If motor slows down a lot and groans to pull load, winch is probably overloaded. Reduce the amount of load being pulled.

Corrective Action:

Recharge or replace battery and confirm good clean connections for both positive (+) and ground (-) wires.

Motor runs but winch fails to pull strap

Corrective Action:

If the winch is new or has a new strap installed, it may take several revolutions of the winch reel before the strap tightens sufficiently on the reel to begin pulling a load.

Corrective Action:

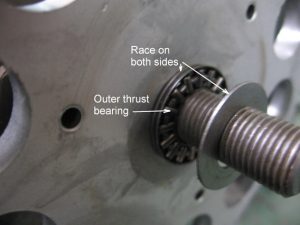

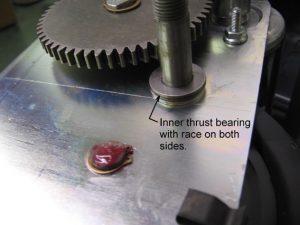

Tighten clutch knob. If tightening the knob does not solve the problem, but you know for sure the clutch is slipping, then there are two possible causes. The thrust bearings could be worn out or the clutch pad could be damaged. To investigate, remove the slotted nut from the center of the clutch knob, the clutch knob and the winch cover. On the clutch stud you will see the outer thrust bearing with a hardened bearing race (flat washer) on both sides. Lift this bearing and both of the gears off of the stud and notice that there is a small spring washer between them. The inner thrust bearing and two races can then be removed. There will be additional spacer washers on the stud and these should remain in place. Check the condition of both of the thrust bearings and the races and replace if noticeably worn, dry or burned. Order and install thrust bearing kit 5703194, which includes two bearings and four races. Examine the condition of the clutch pad. This is bonded to the large gear in newer models or bonded to the flange of the small gear in older models. If there are portions of the clutch pad missing or torn away, or any other significant damage to the pad, a replacement is necessary. If the clutch pad in your winch is bonded to the large gear, you can replace just that gear. Order 120 tooth gear assembly 306102. If the clutch pad in your winch is bonded to the clutch gear flange it will be necessary to order clutch gear assembly 306100 in addition to the 120 tooth gear. Reassemble the clutch by the following procedure. Place one of the thrust bearings (with a race on each side) on the clutch stud. Next install the clutch gear and the spring washer oriented as shown in the photo on the stud followed by the 120 tooth gear turned with the pad facing the clutch gear. Install the outer thrust bearing (with a race on each side) and then reinstall the cover, clutch knob and slotted nut.

Corrective Action:

Remove the winch cover and reinstall and tighten the clutch knob. Run the winch and observe which parts are turning and which are not. This should make the source of the problem obvious. Refer to the owner’s manual or website for the necessary repair parts.

Circuit breaker trips

Corrective Action:

The circuit breaker is designed to cut power to the winch in the event of a substantial overload. It will automatically reset after a short cooling period. Note that the circuit breaker will not protect the motor from damage due to excessive run time.

Corrective Action:

If problem persists after confirming that the load being pulled is within the capacity of the winch, then replace circuit breaker 204039.

Winch will not hold load

Corrective Action:

Tighten clutch knob.

Corrective Action:

Remove the winch cover to observe which parts are moving as the load slips out. This should pinpoint the problem. If the motor shaft is turning, replace the roller clutch assembly 304698.

Strap will not freewheel

Corrective Action:

First confirm that clutch knob is in freewheel position. Then with no load on winch jog power switch to see if clutch will open and allow freewheeling. If this does not work, remove any load from the winch and remove the winch cover. Then gently pry the clutch gear and mating gear apart by inserting a screwdriver between them.

Strap damage

Corrective Action:

The strap is considered a perishable item and will periodically need to be replaced. Follow these suggestions to maximize strap life: It is essential that the winch is aligned with the load so that the strap goes straight into the front opening of the winch without severely rubbing on the edges of the opening. Allowing the strap to rub on anything, or allowing it to feed onto the winch reel in a bunched up or folded over fashion will quickly damage and weaken the strap. The strap must lay flat on the winch drum. Strap can easily be cut if it is under tension and allowed to contact any metal edge, even if it does not seem especially sharp. Keep the strap in good condition and replace when damaged.

Strap breaks

Corrective Action:

See Strap damage section above.

Corrective Action:

The winch has sufficient power to break the strap if overloaded. Monitor load carefully to prevent a sudden rise in strap tension. Keep strap in good condition and replace when damaged.

Hook spreads open

Corrective Action:

Make certain that load is fully engaged into the throat of the hook allowing the safety latch to close. Engaging only the point of the hook on the load could cause hook to open up or break.

Corrective Action:

Overloading the hook will cause it to spread open and possibly break. Reduce the load.